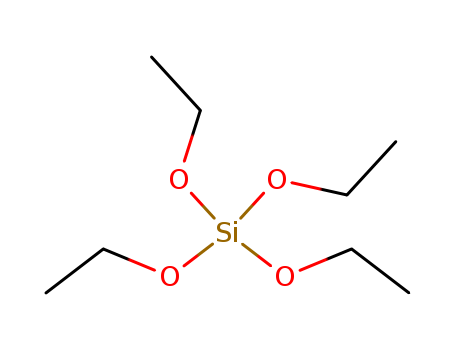

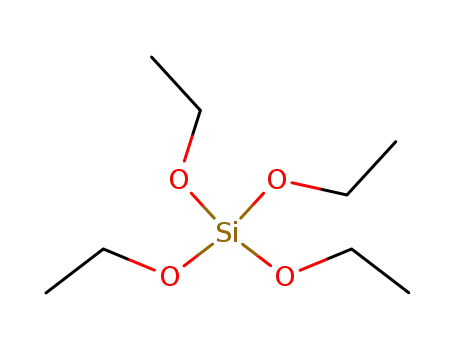

78-10-4

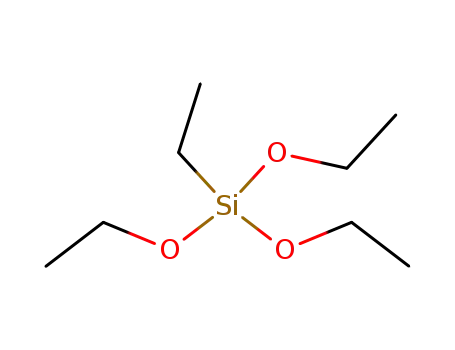

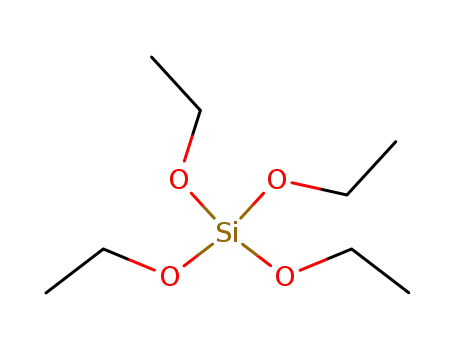

- Product Name:Tetraethoxysilane-28

- Molecular Formula:C8H20O4Si

- Purity:99%

- Molecular Weight:208.33

Product Details

China cas 78-10-4 factory wholesale Tetraethoxysilane-28 at affordable price

- Molecular Formula:C8H20O4Si

- Molecular Weight:208.33

- Appearance/Colour:clear colorless liquid with a faint odor

- Vapor Pressure:<1 mm Hg ( 20 °C)

- Melting Point:-77 °C

- Refractive Index:n20/D 1.382(lit.)

- Boiling Point:165.499 °C at 760 mmHg

- Flash Point:46.667 °C

- PSA:36.92000

- Density:0.939 g/cm3

- LogP:1.56800

Tetraethyl orthosilicate(Cas 78-10-4) Usage

|

Ethyl silicate |

Ethyl silicate is also known as Tetraethyl orthosilicate,colorless, transparent liquid with special smell. Stable under the condition of anhydrous, when encountering water, it decomposes into ethanol and silicic acid, cloudy in moist air, soluble in alcohol, ether and other organic solvents. It is toxic, strong irritative to the human eye and respiratory tract. it is prepared by distillation after the reaction of silicon tetrachloride with ethanol. It is used for producing heat and chemical resistant coatings and preparing silicone solvent, can also be used in organic synthesis, the basic raw material for preparing advanced crystal, used as optical glass processing agent, binders, insulation materials for electronics industry, etc. Ethyl silicate itself is not able to bind, if ethyl silicate is used as refractories binding agents, it must be hydrolyzed before use. TEOS hydrolysis reactions under conditions of water only is very slow, if that is under catalytic action of acid (H +) or base (OH-) catalysis, hydrolysis rate is greatly accelerated. Hydrochloric acid is generally used as a catalyst, as if alkali is as a catalyst, hydrolytic gel will happen soon in hydrolysis solution, leaving the hydrolytic sol destabilized, and thus lose the ability to bind, ethyl silicate hydrolysis under acid catalysis is as follows: The hydrolysis is essentially the ethoxy (C2H5O-)of ethyl silicate is substituent by hydroxyl (-OH) of water, with the result that ethyl silicate (Si4-OC2H5) converted into a silanol group (Si4-OH). Silanol are highly active, can continue to conduct acid exchange reaction or etherification reaction with other silicic acid ethyl or silanols. However, the extent of the hydrolysis reaction is carried out by a certain control, to form a stable hydrolyzate of ethyl silicate. Otherwise, the results of continuous reaction will form a body polyorganosiloxane and lose stability, it becomes insoluble gel, thus lose workability. Stability of ethyl silicate hydrolyzate is adjusted mainly by adding acid or base. When the pH is between 1.5 and 2.5, the gel occurs for a longer time, hydrolyzate is most stable. Lower or higher than this range, hydrolysis prone to gel, the pH is 5-6, the hydrolyzate prone to gel and is most unstable. Thus, the general hydrolyzate should be controlled between 2.0 and 2.5, in order to maintain its stability to maintain a certain working time (the time of construction or molding) after mixed with refractory material. Ethyl silicate hydrolyzate can be used as die casting refractory binding agents, also binding agents for clay, high alumina, corundum, containing zircon, mullite, silicon carbide and castable products. The above information is edited by the lookchem of Yan Yanyong. |

|

Production method |

It is produced by esterification of silicon tetrachloride with ethanol at normal temperature and pressure. |

|

Toxicity grading |

Poisoning |

|

Acute toxicity |

Oral-rat LD50: 6270 mg/kg, Inhalation-rat LCL0: 85 g/cubic meter. |

|

Stimulus data |

Skin-rabbit 500 mg/24 hours moderate. Eyes-rabbit 500 mg/24 hours mild. |

|

Explosive hazardous characteristics |

Can be explosive mixed with air. |

|

Flammability hazard characteristics |

Combustible, fire toxic fumes of silicon oxide emissions. |

|

Storage Characteristics |

Treasury ventilation low-temperature drying, stored separately from oxidants. |

|

Extinguishing agent |

Foam, powder, carbon dioxide, sand. |

|

Occupational standards |

TWA 85 mg/m3, STEL 170 mg/m3. |

|

Production Methods |

Prepared from absolute alcohol and silicon tetrachloride. |

|

Air & Water Reactions |

Flammable. Practically insoluble in water. Reacts slowly with water to form silica and ethyl alcohol [Merck]. |

|

Reactivity Profile |

Tetraethyl orthosilicate reacts exothermically with acids Strong oxidizing acids may cause a reaction that is sufficiently exothermic to ignite the reaction products. May generate with caustic solutions. May generate flammable hydrogen with alkali metals and hydrides. |

|

Hazard |

Moderate fire risk. Strong irritant to eyes, nose, throat. |

|

Health Hazard |

Exposures to ethyl silicate cause adverse health effects. The symptoms of poisoning include, but are not limited to, irritation of the eye, mucous membrane, respiratory tract, respiratory diffi culty, tremor, fatigue, narcosis, nausea, and vomiting. Prolonged periods of skin contact may produce drying, cracking, infl ammation, and dermatitis. As observed in laboratory animals, occupational workers exposed to the chemical substance may suffer from liver and kidney damage, CNS depression, and anemia. At concentrations of 3000 ppm, ethyl silicate causes extreme and intolerable irritation of the eyes and mucous membranes; at 1200 ppm, it produces tearing of the eyes; at 700 ppm, it causes mild stinging of the eyes and nose; and at 250 ppm, it produces slight irritation of the eyes and nose. |

|

Fire Hazard |

HIGHLY FLAMMABLE: Will be easily ignited by heat, sparks or flames. Vapors may form explosive mixtures with air. Vapors may travel to source of ignition and flash back. Most vapors are heavier than air. They will spread along ground and collect in low or confined areas (sewers, basements, tanks). Vapor explosion hazard indoors, outdoors or in sewers. Runoff to sewer may create fire or explosion hazard. Containers may explode when heated. Many liquids are lighter than water. |

|

Safety Profile |

Poison by intravenous route. Moderately toxic by other routes. A skin,mucous membrane, and severe eye irritant. Narcotic in high concentrations. Flammable liquid when exposed to heat or flame; can react vigorously with oxidzing materials. When heated to decomposition it emits acrid smoke and fumes. See also ESTERS. |

|

Potential Exposure |

Ethyl silicate is used as a binder in production of cases and molds for investment casting of metals. The next largest application is in corrosion-resistant coatings; primarily as a binder for zinc dust paints. Miscellaneous uses include the protection of white-light bulbs; the preparation of soluble silicas; catalyst preparation and regeneration; and as a crosslinker and intermediate in the production of silicones |

|

Shipping |

UN1292 Tetraethyl acetate, Hazard Class: 3; Labels: 3-Flammable liquid. |

|

Purification Methods |

Fractionate it through an 80cm Podbielniak type column (p 11) with a heated jacket and partial take-off head. It is slowly decomposed by H2O-and is soluble in EtOH. It is flammable-it irritates the eyes and mucous membranes. [Sumrell & Ham J Am Chem Soc 78 5573 1956, Bradley et al. J Chem Soc 5020 1952, Beilstein 1 IV 1360.] |

|

Incompatibilities |

May form explosive mixture with air. Strong oxidizers; strong acids; water. |

|

Waste Disposal |

Incineration in admixture with a more flammable solvent. |

|

Precautions |

Occupational workers should avoid contact between ethyl silicate and strong oxidizers, water, mineral acids, and alkalis. Workers should use appropriate personal protective clothing and equipment that must be carefully selected, used, and maintained to be effective in preventing skin contact with ethyl silicate. The selection of the appropriate personal protective equipment (PPE) (e.g., gloves, sleeves, encapsulating suits) should be based on the extent of the worker’s potential exposure to ethyl silicate. There are no published reports on the resistance of various materials to permeation by ethyl silicate. |

|

Category |

Flammable liquids. |

|

General Description |

A clear colorless liquid with a faint odor. Flash point 125°F. Less dense than water. Vapors are heavier than air. |

InChI:InChI=1/C17H20N2O2S.Si/c1-3-20-15-9-5-13(6-10-15)18-17(22)19-14-7-11-16(12-8-14)21-4-2;/h5-12H,3-4H2,1-2H3,(H2,18,19,22);/q;+4

78-10-4 Relevant articles

-

Ogier

, p. 118 (1879)

-

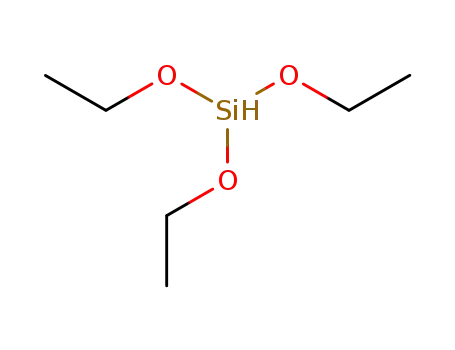

Catalysis of triethoxysilane disproportionation with oligoethylene glycol ethers

Parshina, Lidiya N.,Oparina, Lyudmila A.,Khil'ko, Marina Ya.,Trofimov, Boris A.

, p. 246 - 249 (2003)

Oligoethylene glycol ethers catalyze the...

Mechanochemical method of producing triethoxysilane

Temnikov,Anisimov,Chistovalov,Zhemchugov,Kholodkov,Zimovets,Vysochinskaya, Yu. S.,Muzafarova

, p. 270 - 274 (2019)

A mechanochemical method for synthesis o...

Method for removing methyldichlorosilane and silicon tetrachloride impurities in trimethyl chlorosilane

-

Paragraph 0037-0038; 0045-0046; 0050-0052; 0064; 0079; ..., (2021/08/25)

The invention relates to a method for re...

Sustainable Catalytic Synthesis of Diethyl Carbonate

Putro, Wahyu S.,Ikeda, Akira,Shigeyasu, Shinji,Hamura, Satoshi,Matsumoto, Seiji,Lee, Vladimir Ya.,Choi, Jun-Chul,Fukaya, Norihisa

, p. 842 - 846 (2020/12/07)

New sustainable approaches should be dev...

Method for preparing organosilane by utilizing organosilicone byproduct

-

Paragraph 0021-0023; 0025-0026, (2020/07/13)

The invention relates to the technical f...

METHOD FOR PRODUCING TETRAALKOXYSILANE

-

Paragraph 0055; 0056-0061; 0062; 0063-0066; 0069-0073, (2020/12/01)

An object of the present invention is to...

78-10-4 Process route

-

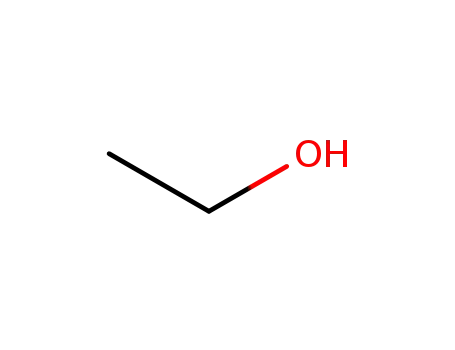

- 64-17-5

ethanol

-

- 78-10-4

tetraethoxy orthosilicate

-

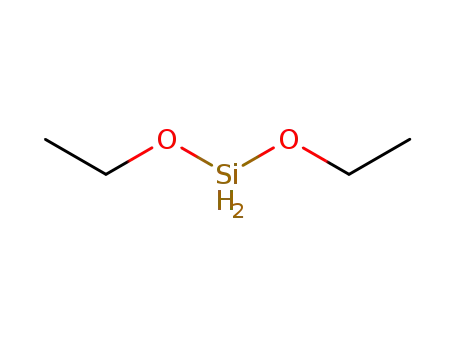

- 18165-68-9

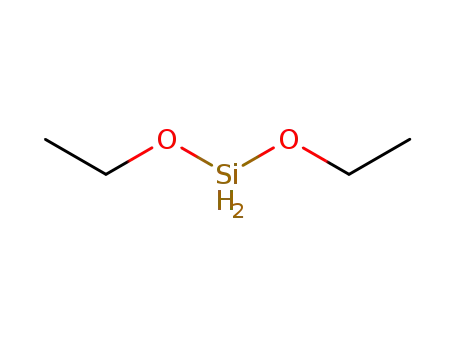

diethoxysilane

-

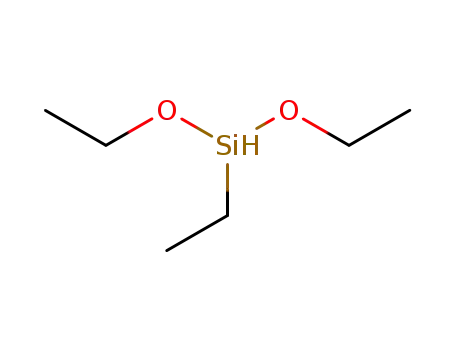

- 13175-88-7

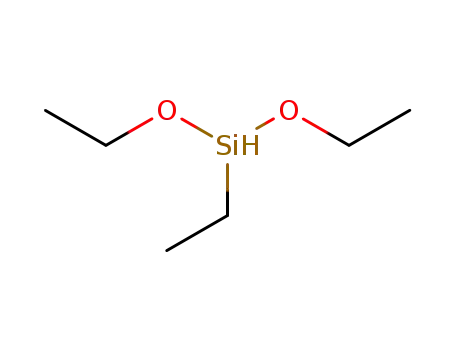

ethyldiethoxysilane

-

- 998-30-1

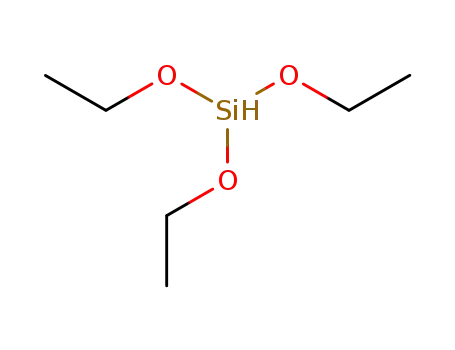

Triethoxysilane

| Conditions | Yield |

|---|---|

|

With thiophene; copper(l) chloride; silicon; at 339.85 ℃; under 607.549 Torr; Further byproducts given;

|

14 % Chromat. 75 % Chromat. 4 % Chromat. 3 % Chromat. |

-

- 64-17-5

ethanol

-

- 7440-21-3

silicon

-

- 78-07-9

ethyltriethoxy silane

-

- 78-10-4

tetraethoxy orthosilicate

-

- 18165-68-9

diethoxysilane

-

- 13175-88-7

ethyldiethoxysilane

-

- 998-30-1

Triethoxysilane

| Conditions | Yield |

|---|---|

|

With copper(I) cyanide; copper(I) oxide; In THERMINOL 59; at 200 ℃; for 16 - 18h; Product distribution / selectivity;

|

|

|

With copper(I) cyanide; undecyl cyanide; copper(I) oxide; In THERMINOL 59; at 200 ℃; for 15h; Product distribution / selectivity;

|

|

|

With copper(I) cyanide; copper(I) oxide; In THERMINOL 59; at 200 ℃; for 20h; Product distribution / selectivity;

|

|

|

With octanedinitrile; copper(I) oxide; In NALKYLENE 500; at 200 ℃; for 15h; Product distribution / selectivity; hydrogen atmosphere;

|

78-10-4 Upstream products

-

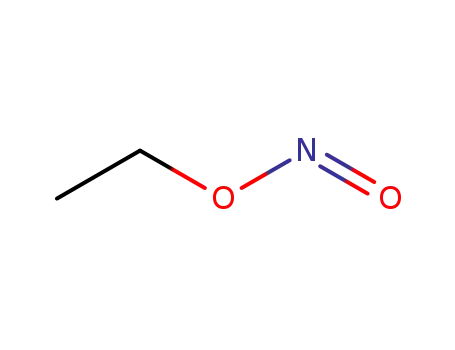

109-95-5

ethyl nitrite

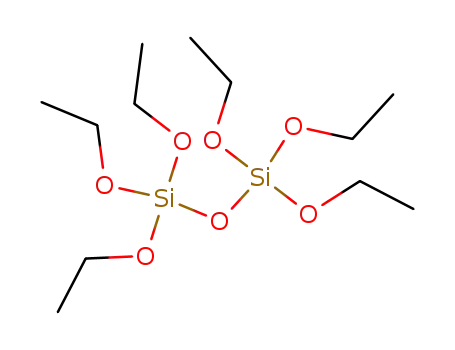

-

2157-42-8

hexaethoxydisiloxane

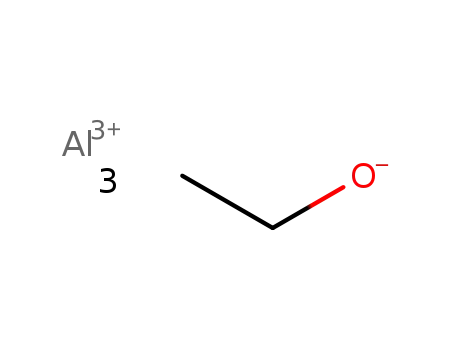

-

555-75-9

aluminum ethoxide

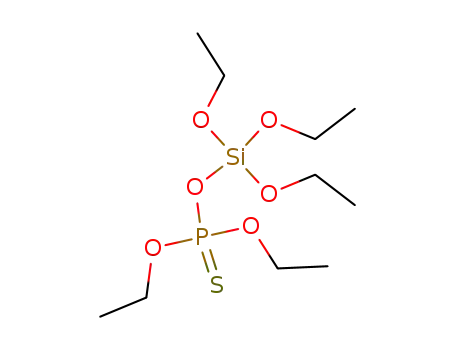

-

17940-30-6

O,O'-diethyl-thiophosphoric tri-O-ethyl-silicic anhydride

78-10-4 Downstream products

-

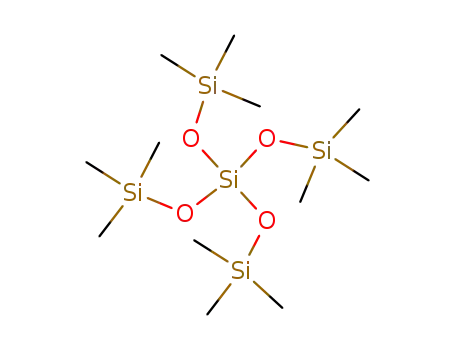

3555-47-3

1,1,1,5,5,5-hexamethyl-3,3-bis(trimethylsiloxy)trisiloxane

-

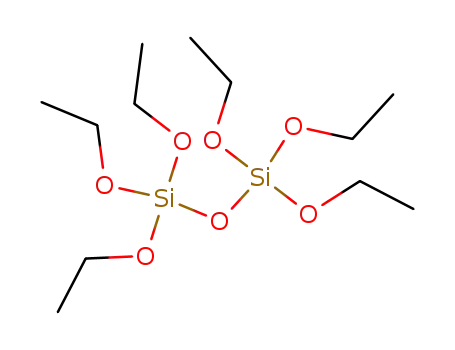

2157-42-8

hexaethoxydisiloxane

-

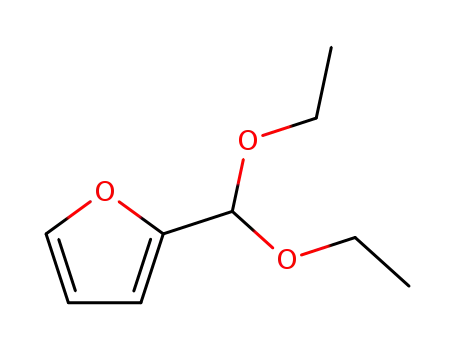

13529-27-6

2-(diethoxymethyl)furan

-

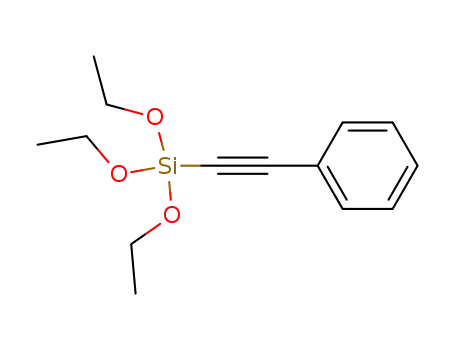

18402-75-0

1-triethoxysilyl-2-phenylacetylene

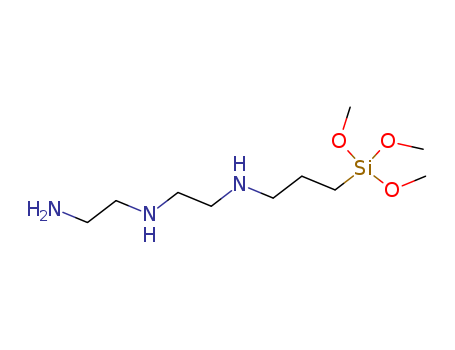

Relevant Products

-

Diethylenetriaminopropylmethyldimethoxysilane

CAS:35141-30-1

-

(66-70% Polydimethylsiloxane)-Ethylene Copolymer, 20-25 cSt

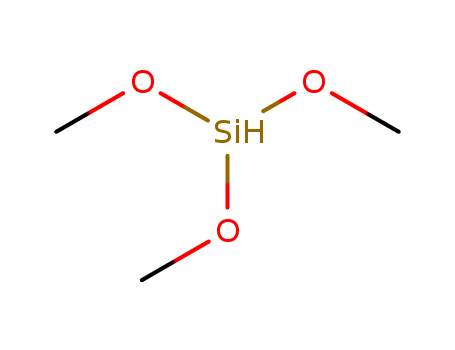

CAS:26710-23-6

-

Trimethoxysilane

CAS:2487-90-3